What We Offer

Audley DTF Printers For Sale

25 Years Industry Experience

Why Our DTF Printers

Advantages

Imagine that you are struggling with the maintenance and repair of your DTF printer and the high cost of consumables, experiencing printing quality concerns, or finding the software too complex to use! How frustrating it is!

As a DTF printer manufacturer, we prioritize minimizing issues and ensuring ease for our clients. We offer superior performance and competitive DTF printer price, providing the best value for investment.

Easy Maintenance And Repair

We offer easy-to-follow instructions and videos on how to keep your printer clean and well-maintained. If you ever need help, our English-speaking technicians are available to provide guidance promptly.

Perfect Print Quality

Our commitment to high-quality printing drives us to use premium components like print heads, DTF ink, and PET film. This ensures exceptional print quality, free from common issues like color inconsistencies and image distortion. To further optimize the print quality and minimize errors, we provide advanced software with built-in tools. Explore our range of DTF printers for sale to experience these benefits firsthand.

Affordable Consumables

To help reduce consumable costs, we offer competitive ink refill pricing and various cartridge sizes. Our ink systems are designed to minimize ink waste and increase efficiency.

Easy-To-Use Software

Our software offers a user-friendly interface and built-in tools that enable users to create high-quality prints effortlessly. With the easy-to-use software, even beginners can achieve professional-looking prints with ease.

Table of Contents

Contact Form

Various DTF Printers For Sale

We provide a range of DTF printers with diverse models to meet various printing needs. Our OEM services can cater to specific requirements. Contact us to learn more about our product offerings and services.

S2030-3

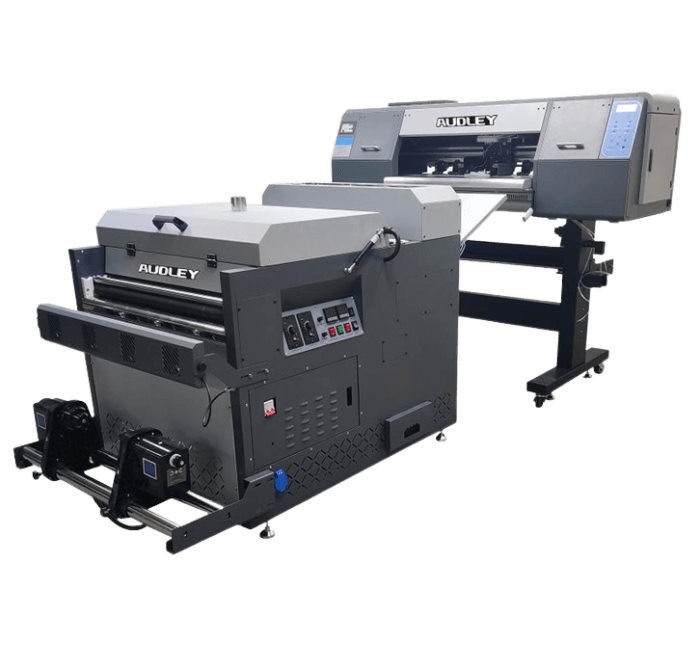

Audley DTF Printer & Powder Shaker Machine

Specification

Print Width: 30cm

Print Head: 2 Heads Epson I3200 A1

Print Speed: 6pass: 7.5sqm/h; 8pass: 5.8sqm/h

Power: 800W+1600W

Rip Software: Maintop / Photoprint

Shake Powder Section: Forward/backward, Spread speed, Static elimination

Heating Temperature: 110-140 degree

S2030-X5

Audley DTF Printer & Powder Shaker Machine

Specification

Print Width: 30cm

Print Head: 2 Heads F1080

Print Speed: 6 pass: 4.2sqm/h; 8 pass: 3.5sqm/h

Power: 800W+1600W

Rip Software: Maintop / Photoprint

Shake Powder Section: Forward/backward, Spread speed, Static elimination

Heating Temperature: 110-140 degree

S2070-3

Audley DTF Printer & Powder Shaker Machine

Specification

Print Width: 70cm

Print Head: 2 Head Epson I3200 A1/ 4720/ F1080,Xp600

Print Speed: 6pass: 9 sqm/h; 8pass: 7.6 sqm/h

Power: 800W+4000W

Rip Software: Maintop / Photoprint

Shake Powder Section: Forward/backward, Spread speed, Static elimination

Heating Temperature: 110-140 degree

S2070-3(4)

Audley DTF Printer & Powder Shaker Machine

Specification

Print Width: 70cm

Print Head: 4 Head Epson I3200 A1/ 4720

Print Speed: 6pass: 15 sqm/h; 8pass: 11.2 sqm/h

Power: 1200W+5000W

Rip Software: Maintop / Photoprint

Shake Powder Section: Forward/backward, Spread speed, Static elimination

Heating Temperature: 110-140 degree

S7070-3

Print Width: 65cm

Print Head: Double I3200-A1

Print Speed: 4passs:15㎡/h; 6passs:9㎡/h; 8passs:7.6㎡/h

Resolution: High ,>2.5pl

Power: 800W+4000W

Heating Temperature: 110-140 degree

8070-3

Print Width: 65cm

Print Head: Four I3200-A1

Print Speed: 4passs:22㎡/h; 6passs:15㎡/h; 8passs:11.2㎡/h

Resolution: High ,>2.5pl

Power: 800W+4000W

Heating Temperature: 110-140 degree

S8074-3

Print Width: 70cm

Print Head: Four I3200

Print Speed: 4passs:34㎡/h; 6passs:24㎡/h; 8passs:17㎡/h

Resolution: 3200 DPI

Power: 800W+4500W

Heating Temperature: 110-140 degree

Estimated Profit Analysis

DTF printing is a burgeoning industry in line with the current trend of environmental protection and labor-saving. Its versatility in printing on various fabrics and time-saving capabilities are fueling its popularity in the digital printing sector. Curious about its profitability? Let’s calculate the profit:

- Cost of Blank T-shirt

A blank T-shirt costs $1.80

- Cost of Consumables

The cost of printing a T-shirt with ink and PET film is $0.2

- Price of a Printed T-shirt

A printed T-shirt sells for $12 to $15

- Attractive Profit

Based on the lowest selling price of $12, T-shirt gross profit = selling price – blank T-shirt cost – consumables cost = $10

2000 pieces are printed every month, and the monthly profit is $20,000! It’s really a profitable business.

PROFESSIONALISM

How We Process Your Order

Pre-sales Consultation

Responsive sales reps are available to answer your questions about products and services within 24 hours. Even if you have not imported a DTF transfer printer from China, we will patiently guide you through the import process.

Turnkey Solution

Want to buy a dtf printing package from China for your business? We provide you with a one-stop solution from proofing, production to installation guidance. If you’re a start-up, we can help with a business plan.

Manufacturing

Every employee of the company strictly abide by the advanced 5S management standards, procurement, production and quality control personnel work closely together to produce high quality machines.

After Sales Technical Support

It’s not hard to solve a problem, but it’s hard to spot it precisely. The tech team will work patiently with you to locate the problem and provide you with nanny-like tech support.

Why Wholesale

DTF Printers From Us?

By working with us, you won’t face the following problems:

1. Waste time and energy in frequently cleaning clogged nozzles, dealing with customer complaints due to poor printing effect, thinking about how to improve efficiency

2. Waste money on frequent replacement components, expensive consumables, and staggering electricity bills

High Quality Printer

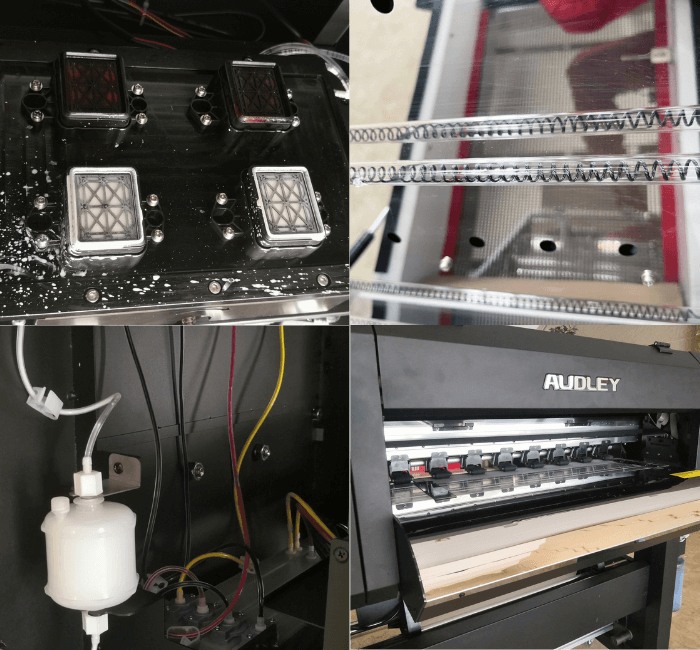

Exclusive technology patent, Highest quality standard. Look in detail at how we have improved the quality of machines:

1. Automatically and intermittently open the circulating pump when starting, so that the ink in the pipeline circulation flow, prevents plugging.

2. Intermittently stir the white ink automatically when the machine is turned on so that the ink is evenly stirred.

3. Built with high-quality materials such as 6mm thick aluminum alloy, industrial-grade conveyor belts, and heavy-duty pressure rollers to enhance durability, accuracy, and stability.

Perfect Printing Effect

Look at how we can improve the quality of printing from various angles:

1. Genuine Epson printhead, smooth ink jet, exquisite picture quality.

2. We have very high requirements for printing accuracy because it is the core factor affecting the printing effect.

3. Strictly screen the ink and PET transfer film quality to ensure no mistakes in every link.

4. Genuine software that is easy to operate. Clear pattern, high degree of restoration.

5. Provide customers with use tutorials in advance to reduce the rate of defective products.

Save Energy and High Efficiency

Does less power save energy? No! Look at the formula: Electricity consumption = power * time. For the same number of jobs, if the power is too small, the time will be prolonged leading to lower printing efficiency and higher electricity consumption; If the power is too large, energy consumption will be wasted. The motor power of our printer is well balanced between energy consumption and efficiency, which can not only print efficiently but also save energy.

Certificated

Our DTF printers have passed CE,SGS and ISO certification, and have been sold at home and abroad and won the five-star praise from 5000+ customers.

We believe that excellent products can stand the test of the market.

Strict QC

In order to ensure the quality of products, we dare not slack off in any link

1. Strictly screen parts suppliers to ensure that each part meets our company’s standards before being stored.

2. From a machine platform to a screw, workers’ ingenuity is hidden everywhere. Countless experiments to get just the right consumable configuration scheme, and print out amazing art finally.

3. Test the printing effect and machine performance repeatedly to ensure that customers are smiling rather than disappointed at the moment they receive the goods.

High Flexibility

No plate-making is required and can be printed in small batches. Small area needed, no big restrictions for site and fund, it’s friendly for both small businesses and big companies.

25 Years of Experience

Our 25 years of industry experience enable us to provide our customers with high-quality DTF printers at competitive prices. Our unwavering dedication to excellence ensures mutually beneficial outcomes. In addition, we offer a range of support services, including skills training, marketing planning, and brand building, to assist our clients in achieving their business objectives.

Good Services

We offer a comprehensive one-stop solution that streamlines the purchasing process for our clients. From design to production and technical support, we take care of everything. Simply provide us with your requirements, and our team will handle the rest.

Highly Trusted By Customers

Customers in more than 100 countries around the world.

Printed Samples

Samples

Sample

Sample

Sample

Sample

Sample

Sample

Sample

Sample

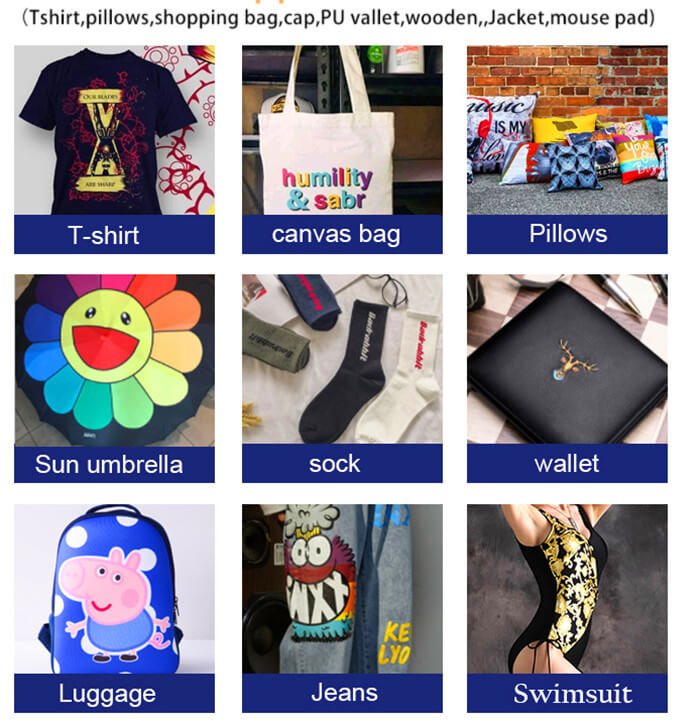

Wide Range Of Application

Application

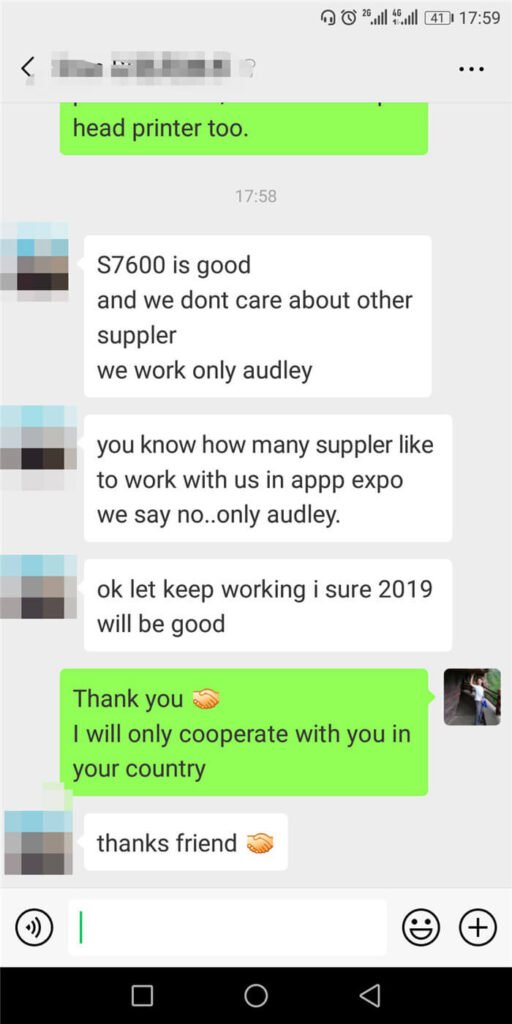

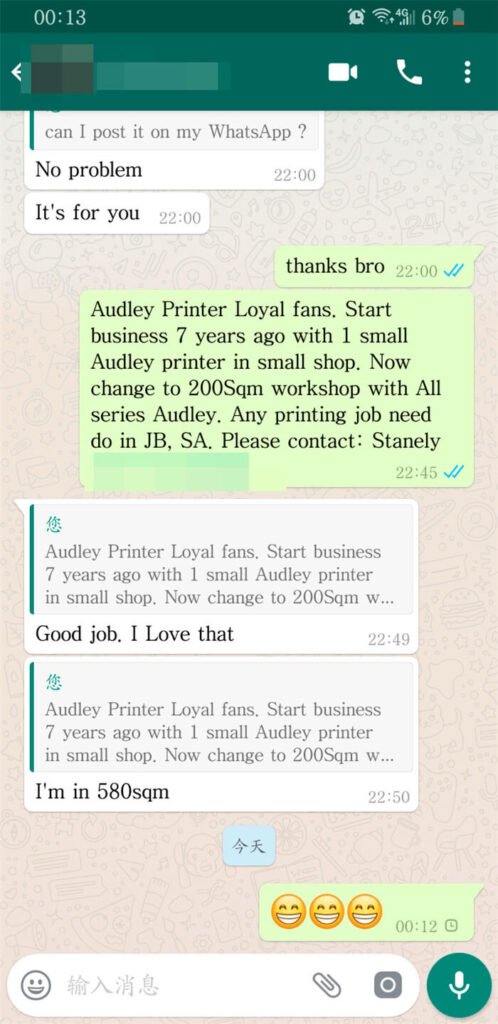

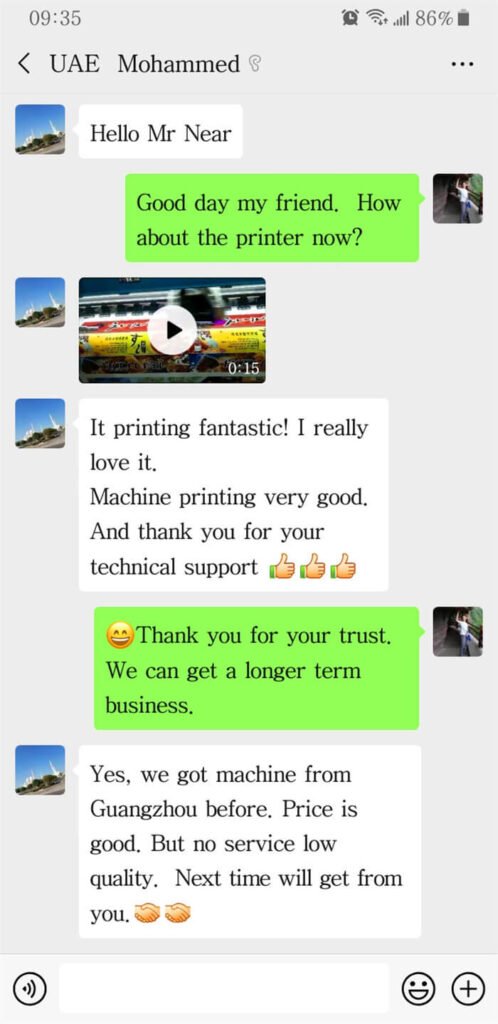

Customer Feedback

Happy Customers From All Over The World

Some customers delete the contact information of other suppliers and only cooperate with us. Some customers grow from family workshops to medium and large printing companies in our company. Customer praise is our original intention to adhere to the output of good quality and good service.

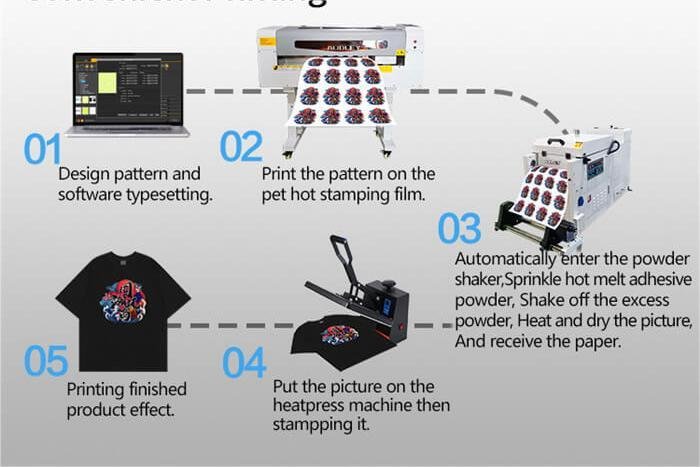

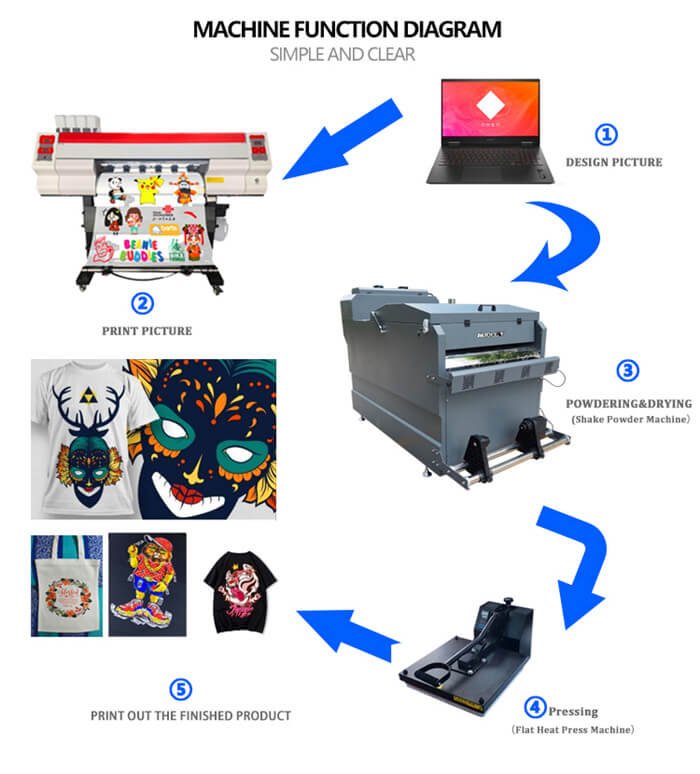

Printing Process

- Design artwork.

- Typeset the artwork and send it to the DTF printer for printing.

- Automatic powder, shake powder, drying, winding.

- Set the appropriate temperature according to the fabric and press the pattern.

- First-class printing effect, bright colors, lifelike.

Frequently Asked Questions

Everything you need to know is right here.

Buy DTF Printer

Consider factors such as the type of materials you will be printing on, the size of your print jobs, and your budget when selecting a printer.

Our company was founded in 1996, we have specialized in producing sublimation textile printer, inkjet printer, hybrid printer, uv printer and laminators for 25 years, and this dtf printer has been in production for 3 years, about 2,000 units can be sold a year, to 80+ countries worldwide.

For the items you purchased, we will arrange shipping by sea or international express delivery to ship and usually the carriers are DHL, FedEx, TNT, and UPS. It shall be quite safe during shipping by sea or air. Additionally, we will purchase insurance as a guarantee for your order.

We can arrange door-to-door logistics transportation, including shipping, import costs, duty tax, etc. After paying, you just wait at home without worrying about shipping and customs clearance.

Installing the machine is a simple process, so there’s no need to worry. We provide detailed English manuals and instructional videos to guide you through the setup and operation of the machine. Additionally, our team of technicians is available to provide online technical support if needed.

We offer a one-year warranty (excluding the print head) and provide a WhatsApp after-sales chat group where our technicians will promptly assist you with any concerns.

Yes, contact us for details and we will give you a special price if you become an agent.

You can pay by bank transfer, Western Union, Payoneer, Transferwise, online credit card, or PayPal.

We will send you a payment confirmation email upon receiving your payment.

Use DTF Printer

A blank T-shirt costs $1.5, the cost of DTF printing consumables is $0.5, and the total cost is $2. It can be sold for at least $15, and the profit of a T-shirt is about $13. If you print 100 pieces a day, it is $1300, one month is $39,000.

If the working time is 8 hours a day, at least 3m² can be printed in one hour, 30m² can be printed in one day, and there are about 40 patterns/m² .1200 pcs pattern can be printed in a day at least, which means 1200 clothes can be printed.

It’s totally washable! Grade 4 color fastness, the color won’t be fading.

It’s fine if the iron can reach a standard high temperature, and it’s best to use a traditional electric iron rather than a steam iron, but we recommend using a professional heat press machine to press.

Hold in the hand repeatedly knead a little glue feel, not obvious from a distance.

Check the ink levels, ensure the printer is properly calibrated, and make sure the correct print settings are selected. Our customer service team can assist with additional troubleshooting steps.

DTF can be applied on a wide range of materials including, cotton, nylon, treated leather, polyester, 50/50 blends and more (light and dark fabrics).

The DTF printer employs a specialized pigment-based ink set that includes cyan, yellow, magenta, black, and white. The white ink is critical for the printing process, while the color pigments are utilized to print designs onto the film.

Knowledges

What is DTF?

DTF printing uses heat to transfer prints onto fabric or materials. It’s more flexible than DTG printing, working on both cotton and poly blends. This makes it a great choice for garment printing and offers more options for materials to print on.

Is DTF better than sublimation?

DTF transfer offers photo-quality images and surpasses sublimation. The fabric’s higher polyester content enhances the image quality, making it more vibrant. DTF designs feel soft to the touch, giving a comfortable wearing experience.

Is DTF better than screen printing?

DTF printing offers more versatility compared to screen printing, allowing you to create designs on a wider range of areas on the garment. It’s also more cost-effective for certain types of jobs and smaller runs, making it a viable option for many businesses.

What maintenance does a printer need?

Regularly clean your printer using a soft cloth or mild alcohol cleaning solution to prevent dust and dirt buildup in small parts. Cover it with a dust net if not in use frequently to prevent dust accumulation.

How often do printers need maintenance?

Usually, it’s advised to update your printer’s maintenance kit every one to two years. But, it’s important to do it annually at a minimum. Regular maintenance checks are crucial, even if your devices are working well and you don’t think it’s needed.

Why do my printer heads keep clogging?

If you don’t use your printer regularly, the ink may dry out and block the printhead, and air bubbles in the ink cartridge can clog the nozzle. To fix minor clogs, you can run a head cleaning cycle and nozzle check on your printer.

How to know if a printhead is clogged?

If your PC or printer’s LCD screen shows that your ink cartridges are full but there is no ink on paper, you might be dealing with a clogged printhead. Additionally, blurry documents and faded images could also indicate the need to remove excess ink.

How to clean DTF printer heads?

First, take a warm and wet paper towel or coffee filter and dab the cartridge gently with the printhead facing downwards to remove any dried ink on the printhead. Then, hold the cartridge with the printhead facing down on a dry paper towel for 2-3 minutes.

How to clean ink cartridges?

Wipe the outside of the cartridges with a paper towel. Pour some isopropyl alcohol on the towel and rub the back and bottom of the cartridges to remove ink buildup. Keep rubbing until all excess ink is gone.

What happens when the temperature of hot stamping is not appropriate?

Improper temperature control during the DTF printing process can cause issues with the adhesive. If the temperature is too low, the glue will not melt into the fabric. Conversely, if it is too high, the glue will not cool sufficiently, resulting in difficulty in removing the film. Maintaining precise temperature control is crucial for achieving optimal results in DTF printing.

Why some places can not be torn off when the film is torn?

Ironing process is not strong press or pressure distribution is not uniform, reset and repress the transparent film, continue ironing can be solved.

What temperature should DTF be pressed at?

Different fabrics require different temperatures. Cotton is 130 to 220 degrees, polyester is 130 to 150 degrees, and chemical fiber is 130 to 220 degrees.

DTF hot peel vs cold peel

Hot peel film is recommended for printing larger patterns like the front and back of garments, whereas cold peel film is better suited for printing thinner lines like back collars and letters.