Choosing the right ink for your direct-to-film (DTF) printer can be challenging. With so many options available, it can be difficult to determine which one is the right fit for your needs. However, the right ink can make a big difference in the quality of your prints. In this guide, we will explore the key features you should look for when choosing DTF ink. From compatibility to color accuracy, we will cover everything you need to know to make an informed decision.

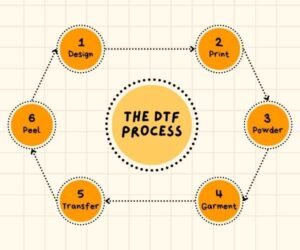

Before we dive into the details, it’s important to understand what DTF ink is and how it works. DTF ink is a type of ink used in DTF printing, which is a method of printing on film. The ink is printed onto a transfer film, which is then transferred to the garment using a heat press. This process allows for high-quality, full-color prints on a variety of fabrics, including cotton, polyester, and blends.

What Type Of Ink Is Used For DTF?

While DTF printing may resemble transfer printing at first glance, it actually requires a specific type of water-based ink that is specially formulated for DTF printing.

DTF ink, also known as direct-to-film ink, is specifically designed for this printing method. These inks are made with opaque pigments and come in cyan, magenta, yellow, black, and white. They are formulated to adhere to PET film media and provide excellent resistance to water and washing.

Calculate The Ink Inventory Firstly

The first thing to consider when choosing the right DTF ink is ink quantity you will need.

According to the number of daily prints and printer specifications to calculate how many DTF films used per day, according to the number of DTF films to calculate how much ink inventory need to prepare.

For example, if you print 1000 A4 prints on an Audley s2070-3 DTF printer and it takes 8 hours, then you need 1 roll of 60cm film. 1 roll of 60cm film requires 1200ml of white ink and 600ml of CMYK colour ink, so you can calculate how much ink is consumed each day. And how much ink you need to get in stock.

How to Choose the Right DTF Ink?

Now, let’s take a closer look at the key features to consider when choosing DTF ink.

Compatibility

One of the most important factors to consider when choosing DTF ink is compatibility. The ink you choose must be 100% compatible with your printer’s original ink. If the ink is not compatible, it can cause clogging or other issues with the printer head, which can lead to poor print quality or even damage to the printer. Look for ink that is specifically designed for your printer model and that has been tested and approved by the manufacturer.

In addition to being compatible with your printer, the ink should also have high compatibility with other materials used in the printing process. This includes the transfer film, the adhesive powder, and the fabric. The ink should be formulated to work seamlessly with these materials, ensuring that the final print is of the highest quality.

Color Accuracy

Another important factor to consider when choosing DTF ink is color accuracy. The ink should be capable of producing bright, vibrant colors that match the original colors as closely as possible. This is especially important for printing logos, images, or other designs that require precise color matching.

Look for ink that has been tested for color accuracy and that has a wide color gamut. The wider the gamut, the more colors the ink is capable of producing, which can lead to more accurate and vibrant prints. Some DTF inks also have the ability to produce metallic or fluorescent colors, which can add a unique look to your prints.

Fastness and Resistance

The durability of the print is another important factor to consider when choosing DTF ink. The ink should have high light fastness and washing resistance, meaning that the colors do not fade or wash out over time. Look for ink that has been tested for these properties and that has a rating of at least 4-5 on the dry rubbing and wet rubbing fastness scale.

In addition to light fastness and washing resistance, the ink should also be resistant to chemicals and other environmental factors. This includes exposure to heat, humidity, and UV light. The ink should have high chemical stability, meaning that it is not easily affected by these factors and will maintain its color and quality over time.

Safety and Environmental Protection

Additionly, it is important to choose DTF ink that is safe and environmentally friendly. The ink should be free of harmful substances, such as heavy metals or phthalates, and should meet all relevant safety standards. Look for ink that is certified by organizations such as OEKO-TEX or REACH.

In addition to being safe, the ink should also be environmentally friendly. Look for ink that is made from renewable resources and that has a low environmental impact. Some DTF inks are also recyclable, which can help reduce waste and minimize the environmental impact of the printing process.

Drying Time

Drying time can affect your productivity and print quality. Some inks may dry too quickly, causing clogging or blocking of the printer head, while others may take too long to dry, resulting in smudging or bleeding. Look for inks that have a reasonable drying time, depending on your printing speed and substrate type.

Price

DTF inks are available at different price points, and the cost of the ink can vary depending on the brand, quality, and other factors. While it is important to invest in high-quality ink, it is also important to consider the price of the ink and how it fits within your budget.

Before purchasing DTF ink, consider the price of the ink and how it fits within your budget. It is also important to compare the prices of different inks to ensure that you are getting the best value for your money.

Conclusion

Choosing the right DTF ink is essential for achieving high-quality, durable prints. When choosing ink, look for compatibility, color accuracy, fastness and resistance, and safety and environmental protection. By considering these factors, you can ensure that you choose an ink that meets your needs and delivers the best possible results.