As a sticker business owner, you know the importance of producing high-quality stickers that will satisfy your customers’ needs. However, choosing the right sticker printing machine can be overwhelming, especially with the variety of options available in the market today. That’s why we’ve compiled this comprehensive guide to help you make an informed decision when selecting a sticker printing machine that best suits your business needs. In this guide, we’ll cover the essential factors to consider when choosing a sticker printing machine, the different types of sticker printing machines, and their pros and cons.

Considerations for Choosing a Sticker Printing Machine

Before you spend your hard-earned money on a sticker printing machine, you need to consider the following factors:Price of the Sticker Printing Machine

The price of the sticker printing machine is a crucial factor to consider as it will determine your budget. The cost of a sticker printing machine varies, depending on its features, brand, and printing technology. Some sticker printing machines are cheap, while others are expensive. However, it’s essential to remember that a high price doesn’t always mean better quality. You can find a sticker printing machine that suits your business needs and budget. When considering the price, you need to factor in the cost of maintenance, repairs, and ink cartridges. Some sticker printing machines require expensive ink cartridges, which can increase your overall printing costs.Printing Quality

The quality of the stickers is critical to your business’s success. Low-quality stickers will not only disappoint your customers but also ruin your reputation. When choosing a sticker printing machine, you need to consider the printing quality. The printing quality is determined by the printing technology used by the machine. It’s essential to choose a machine that produces high-quality stickers that meet your customers’ expectations.Printing Speed

The printing speed is another crucial factor to consider when choosing a sticker printing machine. The printing speed varies, depending on the machine’s technology and features. If you have a high volume of orders, you need a machine that can produce stickers quickly without compromising quality. However, if you have a low volume of orders, the printing speed may not be a significant concern.Printing Volume

The printing volume is the amount of stickers a machine can produce in a given period. If you have a high volume of orders, you need a machine that can handle the workload without breaking down. However, if you have a low volume of orders, you can choose a machine that produces stickers in small quantities.Printing Materials

The printing materials you will be using for your stickers will affect the type of machine you choose. Some machines can only print on specific materials, while others can print on a variety of materials. It’s essential to choose a machine that can print on the materials you intend to use for your stickers.Stickers’ Size

The size of the stickers you will be printing is another factor to consider when choosing a sticker printing machine. Some machines can only print small stickers, while others can print larger ones. It’s essential to choose a machine that can print the size of stickers you need for your business.Stickers’ Type

Stickers come in different types, the most common types of stickers include:Paper Stickers

Paper stickers are the most common type of stickers, and they are easy to print. They are made of paper, which makes them affordable and easy to dispose of. If you’re printing paper stickers, you can use an inkjet or laser printer.Vinyl Stickers

Vinyl stickers are durable and weather-resistant, making them suitable for outdoor use. They are made of vinyl material, which makes them more expensive than paper stickers. If you’re printing vinyl stickers, you need a machine that can handle the material’s thickness and durability.Clear Stickers

Clear stickers are transparent and can be used for a variety of applications. They are made of clear vinyl material, which makes them more expensive than paper stickers. If you’re printing clear stickers, you need a machine that can handle the material’s transparency and durability.Die-Cut Stickers

Die-cut stickers are custom-shaped stickers that require a machine that can cut the stickers into the desired shape. If you’re printing die-cut stickers, you need a machine that can handle the cutting process.Waterproof Stickers

Waterproof stickers are designed to withstand exposure to water and other liquids. They are made of vinyl or polyester material, which makes them more expensive than paper stickers. If you’re printing waterproof stickers, you need a machine that can handle the material’s thickness and durability.Ease of Use

The ease of use is another factor to consider when choosing a sticker printing machine. The machine should be easy to set up, operate, and maintain. You don’t want to spend hours trying to figure out how to use the machine or waste money on repairs and maintenance.Connectivity

The connectivity of the machine is another factor to consider. Some machines require a wired connection to a computer, while others can connect wirelessly. If you prefer wireless connectivity, you need a machine that has Wi-Fi or Bluetooth capabilities.Maintenance and Support

The maintenance and support of the machine are crucial to its longevity and performance. You need a machine that comes with a warranty and reliable customer support. You also need to consider the cost of maintenance and repairs.Types of Sticker Printing Machines

There are different types of sticker printing machines, each with its pros and cons. The most common types include:Heat Transfer Sticker Printing Machines

Heat transfer sticker printing machines are commonly used to produce a variety of stickers, including promotional stickers, bumper stickers, product labels, and more. These machines are particularly popular in the fashion and apparel industry, where they are used to produce custom t-shirts, hats, and other apparel items.Advantages

One of the most significant advantages of heat transfer sticker printing machines is that they can produce high-quality, full-color designs with intricate details. These machines use a combination of heat and pressure to transfer the design onto the sticker material, resulting in a long-lasting, vibrant print. Additionally, heat transfer sticker printing machines are easy to use, require minimal setup time, and can handle a variety of sticker materials, including vinyl, polyester, and more. Another advantage of heat transfer sticker printing machines is that they are versatile and can produce stickers in different shapes and sizes. This makes them an ideal choice for custom sticker printing, as customers can choose the size, shape, and design that best suits their needs. Additionally, heat transfer sticker printing machines are cost-effective, making them a popular choice for small to medium-sized businesses that require high-quality stickers without breaking the bank. Finally, heat transfer sticker printing machines can produce stickers with a variety of finishes, including glossy, matte, and metallic. This allows businesses to create custom stickers that match their branding and marketing efforts.Disadvantages

While heat transfer sticker printing machines have many advantages, they also have some disadvantages. One of the most significant disadvantages is that they are not suitable for large-scale printing. Heat transfer sticker printing machines are designed for small to medium-sized runs and are not ideal for printing thousands of stickers at once. Additionally, these machines require a skilled operator to ensure that the design is properly aligned and that the sticker material is not damaged during the printing process. Another disadvantage of heat transfer sticker printing machines is that they require a specialized printer, which can be expensive to purchase and maintain. Additionally, these machines can only print designs that are smaller than the printer’s size, which can limit the size of stickers that can be produced. Finally, heat transfer sticker printing machines are not suitable for all types of sticker materials. They work best with vinyl and polyester materials, and may not be able to produce high-quality prints on other materials.Solvent Sticker Printing Machines

Solvent sticker printing machines are suitable for a wide range of applications, including vehicle graphics, wall graphics, outdoor signs, and window graphics. These stickers can be used on a variety of surfaces, including glass, metal, and plastic, making them versatile. Additionally, solvent stickers can be contour cut, allowing for intricate designs and shapes.Advantages

Solvent sticker printing machines have several advantages over other types of printing machines. Firstly, they are capable of printing high-quality images with vibrant colors. Secondly, solvent inks are waterproof and UV resistant, making them ideal for outdoor use. Thirdly, solvent sticker printing machines can print on a range of materials, including vinyl, PVC, and polyester. This makes them suitable for creating stickers for different applications, including vehicle graphics, signage, and promotional materials. Furthermore, solvent sticker printing machines are also known for their speed and efficiency. They can produce large quantities of stickers in a short period, making them ideal for businesses that require a high volume of stickers. Additionally, solvent sticker printing machines are easy to operate and require minimal maintenance, making them a cost-effective option for businesses. Finally, solvent sticker printing machines are compatible with a range of software and hardware, making it easy to create custom designs and print them quickly. This makes them ideal for businesses that require personalized stickers for their products or promotional materials.Disadvantages

Despite their many advantages, solvent sticker printing machines also have some disadvantages. Firstly, solvent inks emit volatile organic compounds (VOCs) during the printing process, which can be harmful to the environment and human health. Therefore, it is essential to ensure proper ventilation when using solvent sticker printing machines. Secondly, solvent sticker printing machines require careful maintenance to ensure optimal performance. The print heads must be cleaned regularly, and the ink cartridges must be changed frequently to prevent clogging and other issues. This can be time-consuming and require additional resources, such as cleaning solutions and replacement parts. Finally, solvent sticker printing machines require a significant initial investment. They are more expensive than other types of printing machines, and the cost of ink cartridges can also be high. Therefore, they may not be a viable option for small businesses or those with a limited budget.Dye-Sublimation Sticker Printing Machines

Dye-sublimation printing is a process where ink is transferred onto a substrate through a heat press. This process ensures high-quality and long-lasting prints. When choosing a dye-sublimation printing machine for your sticker printing business, it is important to consider the pros and cons and choose a machine that suits your specific needs and budget.Advantages

Dye-sublimation printing machines have several advantages over other printing technologies, such as:- High-quality prints: Dye-sublimation printing ensures high-quality prints with sharp and vibrant colors. The prints are long-lasting and do not fade easily, making them ideal for outdoor use.

- Customization: Dye-sublimation printing machines offer a high level of customization, allowing you to print any design or pattern on your stickers. This makes them ideal for creating unique and personalized stickers for your customers.

- Versatile: Dye-sublimation printing machines can be used to print on a wide range of substrates, including vinyl, paper, and fabric. This makes them ideal for creating stickers of all kinds.

Disadvantages

While dye-sublimation printing machines offer several advantages, they also have their drawbacks, such as:- Cost: Dye-sublimation printing machines are expensive compared to other printing technologies such as inkjet and laser printers. The cost of the machine, ink, and paper can be a significant investment for a small sticker printing business.

- Limited substrates: While dye-sublimation printing machines can print on a wide range of substrates, they are not suitable for printing on some materials such as wood and metal.

- Time-consuming: Dye-sublimation printing is-consuming process, and it can take up to several minutes to print a single sticker.

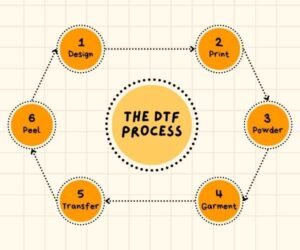

DTF Printing Sticker Printing Machines

DTF printing machines are ideal for a wide range of applications, including the creation of custom stickers for businesses, organizations, and individuals. They can be used to create promotional stickers, product labels, bumper stickers, and much more.Advantages

One of the main advantages of DTF printing machines is that they can print on a wide range of materials, from vinyl to fabric. This makes them ideal for creating custom stickers for a variety of purposes. Additionally, DTF printing machines produce high-quality prints with vibrant colors and sharp details, making them perfect for printing logos and other designs. Finally, DTF printing machines are easy to use and require minimal setup time, making them an ideal choice for businesses of all sizes. Another advantage of DTF printing machines is that they are highly efficient. They can print large quantities of stickers quickly and accurately, which is essential for businesses that need to produce large quantities of stickers on a regular basis. Additionally, DTF printing machines are highly customizable, allowing users to create custom designs and logos that are unique to their business. Finally, DTF printing machines are highly cost-effective. They are much cheaper than traditional printing methods, such as screen printing, and require less maintenance and upkeep. This makes them an ideal choice for businesses that want to save money on their sticker printing needs.Disadvantages

While DTF printing machines have many advantages, they also have some disadvantages that should be considered. One of the main disadvantages of DTF printing machines is that they are not suitable for printing large stickers. This is because the printing area is limited, which means that large stickers will need to be printed in sections, which can be time-consuming and costly. Additionally, DTF printing machines require regular calibration and maintenance to ensure that they are operating at peak efficiency. Fortunately, DTF printing machines are relatively easy to maintain and require minimal upkeep. Most machines come with detailed instructions and support documentation, which makes it easy for users to perform routine maintenance and repairs.UV Printing Sticker Printing Machines

Sticker printing is a growing industry, and with the advancement of technology, various printing machines have emerged. Among them, UV printing sticker printing machines have become popular for their high-quality output and efficiency. However, like any other technology, UV printing machines have their advantages and disadvantages.Advantages

- High-quality output: The UV printing process produces high-quality, vibrant, and sharp images that are resistant to fading and scratches.

- Fast printing speed: UV printing machines have a high printing speed, and the printed stickers can be immediately processed without any drying time.

- Versatility: UV printing allows printing on a variety of materials, including plastic, glass, metal, and wood. This makes it a versatile option for printing on different types of stickers.

Disadvantages

- Expensive setup cost: UV printing machines require a significant initial investment. The cost of purchasing and setting up the machine is high compared to traditional printing methods.

- Limited color range: UV printing machines have a limited color range compared to other printing methods, such as offset printing. This can be a drawback for printing stickers that require a wide range of colors.

- Hazardous materials: The inks used in UV printing contain hazardous chemicals that are harmful to the environment and health. Proper safety measures must be taken when handling the inks and disposing of the waste.

Screen Printing Sticker Printing Machines

Screen printing is a printing technique that involves creating a stencil or screen, which is then used to transfer ink onto a substrate.Advantages

- High-quality prints: Screen printing produces high-quality prints that are crisp, clear, and vibrant. This is because the ink is applied evenly and the colors are mixed accurately, resulting in a clean and vibrant print.

- Durable: Screen printing produces durable prints that are resistant to fading, scratching, and peeling. This is because the ink is cured at high temperatures, which makes it bond more tightly to the substrate and increases its durability.

- Versatile: Screen printing can be used to print on a wide range of substrates, including paper, plastic, metal, and fabric. This makes it a versatile printing method that can be used in various industries, such as packaging, textiles, and advertising.

Disadvantages

- Time-consuming: Screen printing is a time-consuming process that involves multiple steps, including creating the stencil, setting up the printing press, and curing the ink. This can make it less efficient than other printing methods, especially for smaller print runs.

- Limited color options: Screen printing is limited in the number of colors it can print at once. Each color requires a separate stencil and printing pass, which can increase the production time and cost.

- High setup costs: Screen printing requires a significant investment in equipment and supplies, such as screens, inks, and a printing press. This can make it a costly printing method, especially for smaller businesses or those with limited budgets.