As a digital printers’ factory that specializes in producing high-quality DTF printers, we often get asked if DTF printing is the most cost-effective option for apparent printing. The answer to this question is not a simple one, as it depends on various factors such as the printing volume, the complexity of the design, the type of fabric used, and the printing method used. In this blog post, we will explore the cost-effectiveness of DTF printing and compare it with other popular printing methods.

What is DTF Printing?

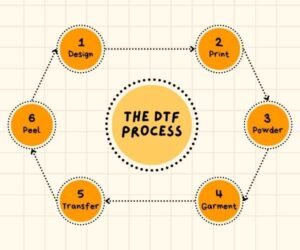

Direct-to-Film (DTF) printing is a relatively new printing method that has gained popularity in recent years. It involves printing the design onto a special film, which is then transferred to the garment using a heat press. DTF printing is known for its ability to print vibrant and detailed designs on a variety of fabrics, including cotton, polyester, and blends. It is also a popular choice for printing on dark or colored fabrics, as it does not require a white underbase like traditional screen printing.

What are the other options for apparel printing?

Heat Transfer Vinyl (HTV)

HTV involves cutting the design out of vinyl and then using heat to transfer the vinyl onto the fabric. It is commonly used for customizing t-shirts, jerseys, and other apparel printing.

Pros: HTV is suitable for small orders and produces durable, long-lasting prints.

Cons: It is not suitable for complex designs or designs with many colors, and the vinyl can peel or crack over time.

Screen Printing

Screen printing is the most common and traditional printing method used for apparel. It involves creating a stencil of the design and then using a mesh screen to apply ink onto the fabric. This method is best suited for large orders of simple designs with few colors.

Pros: Screen printing is cost-effective for large orders and produces vibrant colors that can last a long time.

Cons: It is not suitable for printing complex designs with many colors, and the setup process can be time-consuming.

Direct-to-Garment (DTG) Printing

DTG printing is a digital printing method where the design is printed directly onto the fabric using a specialized printer. This method is ideal for printing highly detailed designs or photographs. DTG printing produces high-quality prints that are long-lasting and do not crack or fade after multiple washes.

DTG printing is suitable for small orders and has a quick turnaround time. However, it is not cost-effective for large orders or designs with a lot of colors.

Dye Sublimation

Dye sublimation involves printing the design onto a transfer paper and then using heat to transfer the design onto the fabric. It is commonly used for printing on polyester or synthetic fabrics.

Pros: Dye sublimation produces high-quality prints with vibrant colors that can last a long time.

Cons: It is not suitable for printing on natural fabrics such as cotton or silk, and the setup process can be time-consuming.

Cost-Effectiveness of DTF Printing VS Heat Transfer Vinyl (HTV)

DTF printing involves printing designs onto a special film that is then transferred onto the fabric using a heat press. The process is similar to screen printing but with the benefits of being able to print full-color designs with fine details. HTV printing involves cutting designs out of vinyl and then applying them to the fabric with a heat press. While HTV printing can be a more affordable option for smaller orders, it can quickly become more expensive than DTF printing for larger quantities.

Both printing methods have their pros and cons, and the best choice ultimately depends on the specific needs of your project. However, for larger orders, DTF printing is generally the more cost-effective option.

In conclusion, while DTF printing may have a higher upfront cost, it can be more cost-effective in the long run for larger orders. It’s important to consider your specific needs and budget when choosing between DTF and HTV printing.

Cost-Effectiveness of DTF Printing VS Screen Printing

When it comes to cost-effectiveness, DTF printing tends to be the more affordable option for smaller batch orders. This is because DTF printing does not require any setup fees, making it a great option for businesses that are just starting out. Additionally, DTF printing allows for full-color designs to be printed without any additional costs, while screen printing requires a separate screen for each color used in the design.

For larger batch orders, screen printing tends to be the more cost-effective option. While screen printing does require a setup fee, the cost per garment decreases significantly as the order size increases. The setup fee is spread out over the entire order, making it more affordable per garment.

Ultimately, the cost-effectiveness of DTF printing versus screen printing depends on several factors, including the size of the order, the number of colors used in the design, and the materials being printed on. For smaller batch orders with full-color designs, DTF printing tends to be the more affordable option. However, for larger batch orders, screen printing may be the more cost-effective choice. As always, it is important to consider all factors and choose the printing method that best suits your business’s needs.

Cost-Effectiveness of DTF Printing VS DTG Printing

DTF printing requires specialized printers, software, and a heat press, while DTG printing requires a specialized printer and ink. Although the initial cost of DTF equipment may be higher than DTG equipment, the cost of DTF transfer paper is significantly lower than DTG ink. Additionally, DTF printing does not require pre-treatment of the garment, which is necessary for DTG printing. Overall, DTF printing has a lower cost.

DTF printing takes longer than DTG printing, but it can produce multiple transfers at once, which can increase efficiency and ultimately reduce production time. Additionally, DTF printing does not require the pre-treatment process that is necessary for DTG printing. The production time will depend on the size and complexity of the design, but DTF printing can be more efficient than DTG printing.

DTF printing produces a crisp, vibrant design that can have a glossy finish. Additionally, DTF printing is known for its durability, as the transfer paper is designed to withstand multiple washes. DTG printing can produce high-quality designs, but the durability of the design depends on the quality of the ink and the pre-treatment process. Overall, both methods can produce high-quality designs, but DTF printing is known for its durability.

Cost-Effectiveness of DTF Printing VS Dye Sublimation Printing

When it comes to cost-effectiveness, DTF printing has several advantages over dye sublimation printing. Here are some of the key factors to consider:

Initial Investment Cost

The initial investment cost for DTF printing is generally lower than dye sublimation printing. DTF printers are typically less expensive than dye sublimation printers, and the film used in DTF printing is also less expensive than the transfer paper used in dye sublimation printing.

Ink Cost

Ink cost is another factor to consider. Dye sublimation ink is typically more expensive than DTF ink, which can make dye sublimation printing more expensive in the long run, especially if you are printing large quantities.

Fabric Cost

DTF printing can be used on a wider variety of fabrics than dye sublimation printing, including cotton, polyester, and even leather. Dye sublimation printing works best on polyester fabrics, which can limit the types of products you can create. When you need to print on natural fabrics such as cotton or silk, you have to use other types of printers, which means the investment costs go up.

Summary

Overall, when considering cost-effectiveness, it’s important to consider all factors, including the size of the order, the number of colors used in the design, the materials being printed on, and the initial and long-term costs of the printing method. Choose the method that best suits your project’s needs and budget.

Why choose us for your DTF printing needs?

For starters, we offer the highest quality DTF printers on the market, featuring the latest printing technology and made with the highest quality materials. Our printers are easy to use and require minimal maintenance, making them perfect for busy businesses looking to streamline their printing process.

In addition to our top-of-the-line printers, we also offer a range of high-quality transfer paper options to ensure that your prints are always crisp, vibrant, and long-lasting. We understand that every business is unique, which is why we offer a range of transfer paper options to suit your specific needs, including light and dark transfer paper, glitter transfer paper, and more.

But our commitment to excellence doesn’t stop with our products. At Audley, we are dedicated to providing exceptional customer service and support to our clients. We offer lifetime after-sale service, ensuring that our clients can always rely on us for assistance and support, even after they’ve purchased our products. Contact us for more details today.