Printing on hats has been a popular trend for decades. It is a great way to promote businesses, sports teams, and even personal branding. However, with the advancements in technology, printing on hats has become even more efficient and cost-effective. Direct-to-film (DTF) printing is a printing method that is becoming increasingly popular in the hats printing industry. This method involves printing designs on a special film and then transferring them onto the hat using heat. In this blog post, we’ll explore the advantages of DTF printing on hats, cost comparison with other printing methods, challenges in adopting DTF printing technology, and the future of the hats printing industry with DTF printing technology.

Advantages of DTF Printing on Hats

DTF printing on hats offers several advantages over other methods of printing. These advantages include:

Cost-Effective Technology

DTF printing technology is cost-effective compared to other printing methods. The equipment is affordable, and the cost of printing is relatively low. With DTF printing technology, you can print on a variety of materials without incurring additional costs.

High-Quality Prints

DTF printing technology produces high-quality prints that are sharp, vibrant, and long-lasting. The prints have a higher resolution and color accuracy than other printing methods. The colors are bright and vivid, and the images are crisp and clear.

Faster Turnaround Time

DTF printing technology has a faster turnaround time than other printing methods. The process is quick, and the prints are ready in a matter of minutes. This is ideal for businesses that need hats printed quickly for events or promotions.

Customization of Designs

DTF printing technology allows for customization of designs. You can create unique designs that are not possible with other printing methods. This is ideal for businesses that want to stand out and make a statement with their hats.

Market Demands for Customized Products

The market demands customized products that are unique and personalized. DTF printing technology allows businesses to meet these demands and offer a product that is tailored to the customer’s needs. This is ideal for businesses that want to differentiate themselves from their competitors.

DTF printing technology is more cost-effective than other printing methods. The cost of equipment is lower, and the cost of printing is relatively low. With DTF printing technology, you can print on a variety of materials without incurring additional costs. Other printing methods such as screen printing and embroidery can be more expensive due to the cost of equipment and materials.

Screen printing requires the creation of screens, which can be expensive. The cost of ink and other materials can also be high. Embroidery requires specialized equipment and materials, which can be expensive. The cost of thread and other materials can also be high. DTF printing technology is a more affordable option for businesses that want to print on hats.

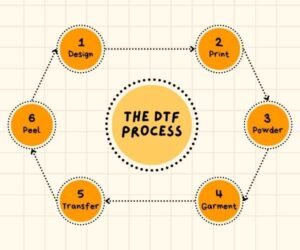

DTF Printing Technology and Process

The DTF printing process involves printing designs on a special film and then transferring them onto the hat using heat. The process is quick and easy and can be done in a matter of minutes. The process involves the following steps:

Step 1: Design Creation

The first step in the DTF printing process is the creation of the design. The design is created using graphic design software and then printed onto a special film using a DTF printer.

Step 2: Film Transfer

The second step in the DTF printing process is the film transfer. The film is placed onto the hat, and heat is applied to transfer the design onto the hat. The heat activates the adhesive on the film and transfers the design onto the hat.

Step 3: Finishing

The final step in the DTF printing process is finishing. The excess film is removed, and the hat is inspected for quality assurance. The hat is then use.

DTF Printing Cost

DTF printing technology can be a cost-effective way to print on a wide range of materials, including hats. The cost of DTF printing will depend on several factors, including:

- Printer cost• Ink cost• Material cost

By considering these factors, businesses can determine the cost of DTF printing and determine whether it is a cost-effective option for their needs.

Choosing the Right DTF Printer

Choosing the right DTF printer is essential for achieving high-quality, vibrant prints on a wide range of materials, including hats. When choosing a DTF printer, it is important to consider the following factors:

- Printer resolution• Ink type and quality

- Printer size and speed

By considering these factors, businesses can choose the right DTF printer for their needs and achieve high-quality, vibrant prints on a wide range of materials, including hats.

DTF Printing on Different Hat Materials

DTF printing technology can be used on a variety of hat materials, including cotton, polyester, and nylon. The prints are vibrant and long-lasting, regardless of the material. This is ideal for businesses that want to print on a variety of hats and materials.

When printing on different materials, it is important to adjust the settings of the DTF printer to ensure the best results. The temperature and pressure settings may need to be adjusted to ensure that the design is transferred onto the hat correctly.

DTF Printing on Cotton Hats

Cotton hats are a popular material for hats due to their softness and breathability. DTF printing technology can be used to print on cotton hats, resulting in high-quality prints that are vibrant and long-lasting. The DTF printing process allows for precise designs and vibrant colors, ideal choice for cotton hats.

DTF printing on cotton hats requires a heat press with a high temperature setting. The heat press should be set to between 320 and 350 degrees Fahrenheit for optimal results. The transfer film should be placed onto the hat, and the heat press should be applied for 15-20 seconds. Once the transfer is complete, the transfer film can be removed, leaving behind a high-quality print on the cotton hat.

DTF Printing on Polyester Hats

Polyester hats are another popular material for hats due to their durability and moisture-wicking properties. DTF printing technology can be used to print on polyester hats, resulting in high-quality prints that are vibrant and long-lasting. The DTF printing process allows for precise designs and vibrant colors, making it an ideal choice for polyester hats.

DTF printing on polyester hats requires a heat press with a lower temperature setting than cotton hats. The heat press should be set to between 290 and 310 degrees Fahrenheit for optimal results. The transfer film should be placed onto the hat, and the heat press should be applied for 10-15 seconds. Once the transfer is complete, the transfer film can be removed, leaving behind a high-quality print on the polyester hat.

DTF Printing on Mesh Hats

Mesh hats are a popular material for hats due to their breathability and lightweight design. DTF printing technology can be used to print on mesh hats, resulting in high-quality prints that are vibrant and long-lasting. The DTF printing process allows for precise designs and vibrant colors, making it an ideal choice for mesh hats.

DTF printing on mesh hats requires a heat press with a lower temperature setting than cotton hats. The heat press should be set to between 290 and 310 degrees Fahrenheit for optimal results. The transfer film should be placed onto the hat, and the heat press should be applied for 10-15 seconds. Once the transfer is complete, the transfer film can be removed, leaving behind a high-quality print on the mesh hat.

Challenges in Adopting DTF Printing Technology

While DTF printing technology offers several advantages, there are also challenges in adopting this technology. These challenges include:

Learning Curve

DTF printing technology requires some training and learning. Businesses may need to invest time and resources into learning how to use this technology effectively.

Quality Control

DTF printing technology requires quality control to ensure that the prints are of high quality. Businesses may need to invest in quality control measures to ensure that the prints are consistent and meet the customer’s expectations.

Future of the Hats Printing Industry with DTF Printing Technology

The future of the hats printing industry is bright with DTF printing technology. This technology offers several advantages over other printing methods and allows businesses to meet the demands of the market for customized products. As more businesses adopt this technology, the cost of equipment and printing will decrease, making it more accessible to smaller businesses.

DTF printing technology will also continue to evolve, offering even more customization options and higher quality prints. This will allow businesses to offer unique and personalized hats that stand out from their competitors.

Conclusion

DTF printing on hats is the future of the hats printing industry. This technology offers several advantages over other printing methods and allows businesses to print high-quality, customized hats at a lower cost. While there are some challenges in adopting this technology, the benefits far outweigh the costs. As more businesses adopt DTF printing technology, the hats printing industry will continue to evolve and offer unique and personalized products that meet the demands of the market.