As a tumbler business owner, choosing the right printing method is crucial to the success of your business. With so many different methods available, it can be overwhelming to determine which one is the best fit for your needs. In this blog post, we’ll be exploring some of the most popular printing methods for tumblers, including UV printing, UV DTF printing, screen printing, sublimation printing, and heat transfer vinyl printing. We’ll be discussing the pros and cons of each method, as well as factors to consider when making your decision.

But first, let’s take a look at why choosing the right printing method is so important. The quality of your tumblers is what sets your business apart from the competition. If your tumblers look cheap or poorly made, customers are unlikely to return. On the other hand, if your tumblers are high-quality and visually appealing, customers are more likely to recommend your business to others and become repeat customers themselves.

With this in mind, let’s dive into the different printing methods available for your tumbler business.

Considerations for Choosing a Printing Method for Your Tumbler Business

Before we dive into the specifics of each printing method, let’s first discuss some of the factors you should consider when making your decision. These include:

Cost

The first factor to consider when choosing a printing method for your tumbler business is your budget. How much can you afford to spend on printing equipment and supplies? Different printing methods have varying startup costs and ongoing expenses. For example, screen printing has high initial costs but can be cost-effective in the long run for large volume production. On the other hand, digital printing has lower startup costs but can be more expensive for high-volume production. Determine your budget and find a printing method that fits within it.

Design Complexity

The type of design you want to print on your tumblers is another factor to consider when choosing a printing method. Different printing methods are suitable for different designs. For instance, screen printing is ideal for simple designs with few colors, while sublimation is perfect for complex designs with multiple colors. If you plan to print complex designs or photographs, sublimation might be the best option. However, if you plan to print simple designs or logos, screen printing might be the best choice.

Quantity

Another factor to consider when choosing a printing method is your production volume. How many tumblers do you plan to produce? Different printing methods have varying production capabilities. For instance, screen printing is ideal for high-volume production, while digital printing is suitable for low to medium volume production. If you plan to produce a large number of tumblers, you might want to consider screen printing. However, if you only plan to produce a few tumblers or custom designs, digital printing might be the best option.

Tumbler Material

The type of material your tumblers are made of can impact which printing method is most suitable. For example, some methods work better on stainless steel tumblers, while others are better suited for plastic or ceramic tumblers.

Tumbler Size and Shape

The size and shape of your tumblers can also impact your choice of printing method. Some methods are better suited for cylindrical tumblers, while others work better on tumblers with irregular shapes or sizes.

UV Printing on Tumblers

UV printing is a popular method for printing on tumblers, as it can produce high-quality, full-color designs. This method uses UV-curable ink, which is cured by exposure to UV light. The ink is applied directly to the tumbler using a printer, and the design is then cured using a UV light.

One of the advantages of UV printing is that it can print on a wide range of materials, including plastic, metal, and glass. It can also print on both flat and cylindrical surfaces, making it a versatile option. Additionally, UV printing is a relatively fast process, making it suitable for both large-scale production.

However, one of the disadvantages of UV printing is that it can be expensive, especially for smaller quantities. It also requires specialized equipment, which can be costly to purchase and maintain. Finally, while UV printing can produce high-quality designs, it may not be suitable for more complex designs or designs with fine detail.

UV DTF Printing on Tumblers

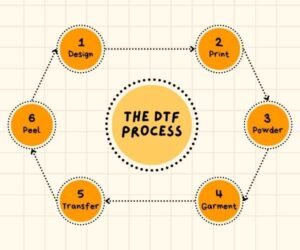

UV DTF printing is a newer printing method that has gained popularity in recent years. It uses a combination of UV-curable ink and direct-to-film printing technology to produce high-quality, full-color designs on tumblers.

One of the advantages of UV DTF printing is that it can produce high-quality designs with fine detail and complex designs. It can also print on a wide range of materials, including metal, plastic, and glass. Additionally, UV DTF printing is a relatively fast process, making it suitable for both small and large-scale production.

However, one of the disadvantages of UV DTF printing is that it can be expensive, especially for smaller quantities. It also requires specialized equipment, which can be costly to purchase and maintain. Finally, UV DTF printing may not be suitable for all tumbler shapes and sizes, and may not produce consistent results on certain materials.

Screen Printing on Tumblers

Screen printing is a traditional printing method that has been used for decades. It involves creating a stencil of the design and applying ink to the tumbler through the stencil using a squeegee. Screen printing can produce high-quality designs with vibrant colors, and is suitable for both small and large-scale production.

One of the advantages of screen printing is that it can produce designs with vibrant colors, even on dark-colored tumblers. It is also a relatively affordable option for larger quantities, as the cost per unit decreases as the quantity increases.

However, one of the disadvantages of screen printing is that it can be time-consuming, especially for smaller quantities. It also requires specialized equipment and expertise, which can be costly to acquire. Finally, screen printing may not be suitable for more complex designs or designs with fine detail.

Sublimation Printing on Tumblers

Sublimation printing is a popular method for printing designs on tumblers. It involves printing the design onto a transfer paper using dye-sublimation ink, and then transferring the design onto the tumbler using heat and pressure.

One of the advantages of sublimation printing is that it can produce high-quality, full-color designs with fine detail. It is also a relatively affordable option for smaller quantities, as the cost per unit is lower than some other printing methods.

However, one of the disadvantages of sublimation printing is that it can only be used on certain materials, such as white or light-colored polyester-coated tumblers. It is also a slower process than some other printing methods, and may not be suitable for large-scale production.

Heat Transfer Vinyl Printing on Tumblers

Heat transfer vinyl (HTV) printing is a popular method for printing designs on tumblers, especially for smaller quantities. It involves cutting out of vinyl using a cutting machine, and then applying the design to the tumbler using heat and pressure.

One of the advantages of HTV printing is that it can produce high-quality designs with vibrant colors, even on dark-colored tumblers. It is also a relatively affordable option for smaller quantities, as the cost per unit is lower than some other printing methods.

However, one of the disadvantages of HTV printing is that it can only be used on certain materials, such as smooth plastic or metal tumblers. It is slower process than some other printing methods, and may not be suitable for large-scale production.

Comparing Cost and Quality

When choosing a printing method for your tumbler business, it’s important to consider both cost and quality. While some methods may be more affordable, they may not produce the same level of quality as more expensive methods.

Additionally, it’s important to consider the cost per unit. Some methods may be more expensive upfront, but may be more cost-effective in the long run for larger quantities.

Ultimately, the best printing method for your tumbler business will depend on your specific needs and budget.

Factors to Consider When Printing

Regardless of which printing method you choose, there are a few factors to consider when actually printing your designs on tumblers. These include:

Prepping the Tumbler

Before printing, it’s important to properly prep the tumbler to ensure the design adheres properly. This may include cleaning the tumbler with rubbing alcohol or sandblasting the surface.

Printing Setup

Each printing method requires a different setup process. Make sure you have the proper equipment and supplies to properly execute the printing process.

Curing the Design

After printing, the design will need to be cured to ensure it adheres properly. This may include using a heat press or UV light, depending on the printing method.

Conclusion

Choosing the right printing method for your t is crucial to the success of your business. By considering factors such as design complexity, quantity, cost, tumbler material, and t size and shape, you can make an informed decision about which printing method to use.

Whether you choose UV printing, UV DTF printing, screen printing, sublimation printing, or heat transfer vinyl printing, remember to properly prep the tumbler, set up the printing process correctly, and cure the design to ensure a high-quality end product.